SEFAR® CleanDisc System

Mesh filter used for the

Inspection of Technical Cleanliness

Clean, safeguarded and easy to handle mesh filter, dispensed to directly perform a technical cleanliness analysis in modern laboratories according to VDA 19.1 & ISO 16232.

How does the

SEFAR® CleanDisc System work?

Made easy: The filter discs dispenses directly to the petri dish by pushing the slider. The Technical Cleanliness analysis can continue immediately.

The membrane filter itself is stored inside a cassette and safeguarded by a tape to avoid cross contamination until usage. The cassette is easy exchangeable and holds the re-fill pack containing the mesh filter. To increase efficiency, up to 600 pcs are in one re-fill pack. The re-fill pack is inserted to the cassette and the cassette is pushed into the dispenser.

- Clean and safeguarded mesh filters

- Easy to operate dispenser

- For left and right handed users

Easy & safe to use

We ensure technical cleanliness without overcomplicating

Combining all requirements from the revised guidelines like VDA 19 as well as the wishes from the users. Put together into a simple to handle system, securing the cleanliness at any time. Independent of the membrane type only one SEFAR® CleanDisc Dispenser is required, allowing a high flexibility. Operating the system is independent of the environment its located in and the users laboratory experience.

Advantages of working with

SEFAR® CleanDisc System

Clean and safeguarded discs

Membranes are stored in closed containers to avoid contamination of dirt from the environment. Complying with the requirements of VDA 19.1 and ISO 16232 is made simple.

Easy operation

By pushing the slider, it withdraws one single filter directly to the petri dish. No more fiddling with the tweezer to get out a membrane or difficulties to open the package.

Controlled cleanliness

Laser cutting and packaging of the mesh filter happens in a cleanroom (type 7). The safety foil secures the level of cleanliness as well as the quality control and the defined level of cleanliness. All helping to easily achieving the blank value.

Laser cut PET mesh filter

Using laser cut discs avoids cross contamination from fraying edges and single yarn pieces. PET ensures constant results in gravimetrical analysis as well as an improved flatness and reduced rolling behavior (PET recommended over Nylon/PA – also from norms).

Detecting white particles

The newly introduced yellow filter membranes now allow the detection of white particles and light colored fibers, while making it possible to detect metal and dark particles at the same time. This brings the automated analysis to a new level.

One dispenser - multiple cassettes

The easy exchangeable cassette system allows to operate one dispenser with multiple cassettes. The unused cassette can be stored and the safety foil secures a clean and safeguarded disc during all time. The label indicates the content in the cassette and help to comply with quality requirements during all time.

SEFAR® CleanDisc Mesh Filter

Yellow membrane to detect white particles

Developed especially for the Technical Cleanliness, the new SEFAR® CleanDisc 5 μm PET mesh filter in yellow now allows the detection of white or bright particles. At the same time, it increases the light-optical contrast of dark and metal particles and increases the reliability of the detection. According the VDA 19.1, the yellow mesh filters allow a norm conform analysis by applying the extended analysis chapter 7.2.3. This feature brings the automated microscopy analysis to a new level allowing to apply the Technical Cleanliness in new application areas like white colored polymers, ceramics or in the additive manufacturing.

Get in touch with us to get some detailed information about how to use it – there are some specialties you need to consider.

What makes the difference?

Foamed membrane vs. Mesh filter

Foamed membrane

Foamed membranes have a sponge – like surface, resulting in a smooth surface especially when detecting very small particle sizes. On the other hand this surface keeps back particles smaller than needed, some even get trapped in the holes. The filter is occupied by the larger amount of fine particles, leading to difficulties in the analyzability. This makes it difficult to detect the single particle with the optical microscope and increases analysis time. Measurement errors may increase and manual corrective steps will be necessary.

Foamed membrane

Foamed membranes have a sponge – like surface, resulting in a smooth surface especially when detecting very small particle sizes. On the other hand this surface keeps back particles smaller than needed, some even get trapped in the holes. The filter is occupied by the larger amount of fine particles, leading to difficulties in the analyzability. This makes it difficult to detect the single particle with the optical microscope and increases analysis time. Measurement errors may increase and manual corrective steps will be necessary.

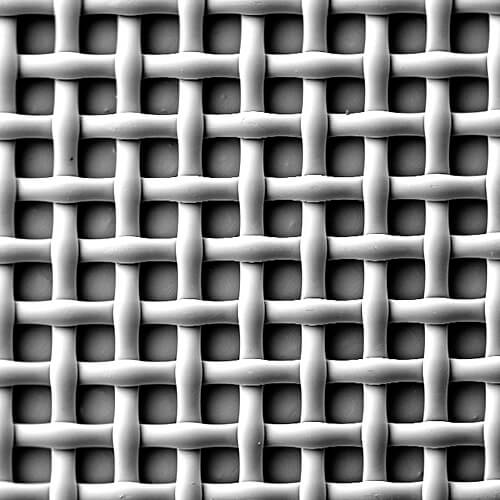

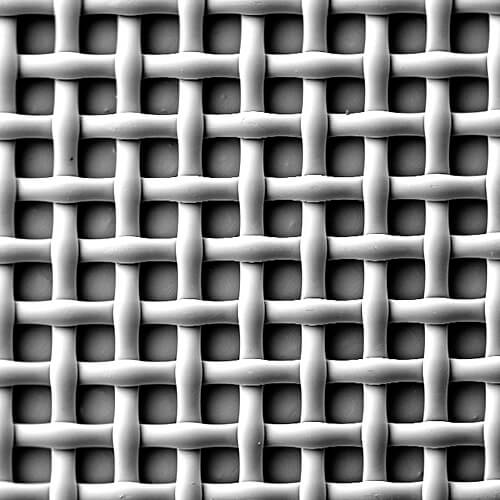

Mesh filter

Mesh filter have a defined geometric pore size resulting in a good particle separation limit. The lower particle load improves feasibility and speed of the automated microscope analysis. The lower humidity and moisture absorption is better for good gravimetrical results (especially PET). The higher temperature resistance allows improved flatness. All the advantages have been the reason to define the PET mesh filter as the standard filter in revised VDA 19.1 guideline.

Mesh filter

Mesh filter have a defined geometric pore size resulting in a good particle separation limit. The lower particle load improves feasibility and speed of the automated microscope analysis. The lower humidity and moisture absorption is better for good gravimetrical results (especially PET). The higher temperature resistance allows improved flatness. All the advantages have been the reason to define the PET mesh filter as the standard filter in revised VDA 19.1 guideline.

Automotive, electronic or medical industry:

The SEFAR® CleanDisc System meets your requirements

Particulate contamination control is an essential part in quality control when producing functionally relevant automotive components. The Technical Cleanliness analysis is a widely accepted and implemented industry guideline. Nowadays, other industries also use the Technical Cleanliness analysis to identify residual dirt on the produced components.

Sefar is supplying the mesh filters from the beginning and understands the industry needs. We are more than happy to share our experience independent of the industry your working in.

Developed with experts, tested by users.

The new design is a result of listening to many users and discussions with experts. Prototypes were tested and modified to ensure all requirements of the revised norms are integrated. Overall, daily business is made easier and more secure.

"We are testing the dispenser with the new re-fill pack since two months and we are absolutely happy! The dispenser works as it is supposed to be and is a tremendous profit to prepare the analysis. The flatness of the disc is comparable to the one in the standard package in best order!"

Tier 1 supplier into the automotive industry

9th Specialist congress in Technical Cleanliness

The central task of a filter is the optimal separation of the particles cleaned from the component and their evaluation. What does “optimal separation” mean and how can this be influenced by the choice and handling of the filter? The lecture highlights the analysis filters in technical cleanliness and provides guidelines for implementing and optimizing the cleanliness analysis.

- Advantages and disadvantages of various analysis filters and practical experience

- Optimization potential in cleanliness analysis by avoiding errors

- Focus on mesh filters as a core element of particle analysis

Isabell Erlenmaier

Industry Manager, Chemicals & Environment – Sefar AG

Sefar AG

Headquarters

Hinterbissaustrasse 12

9410 Heiden

Switzerland